8567891891 | 8567892892

Offering Comfort and Convenience, Security and Safety with Spacious and Luxurious Apartments

If you haven’t visited the model apartment already, then we recommend that you do. The moment you step inside, you’ll realise how good design can create space for more space. The sizes of the rooms, the smart positioning of the windows, and the intelligent layouts, all come together to create a home that is visually appealing and very comfortable.

Clear title land with ZERO litigations

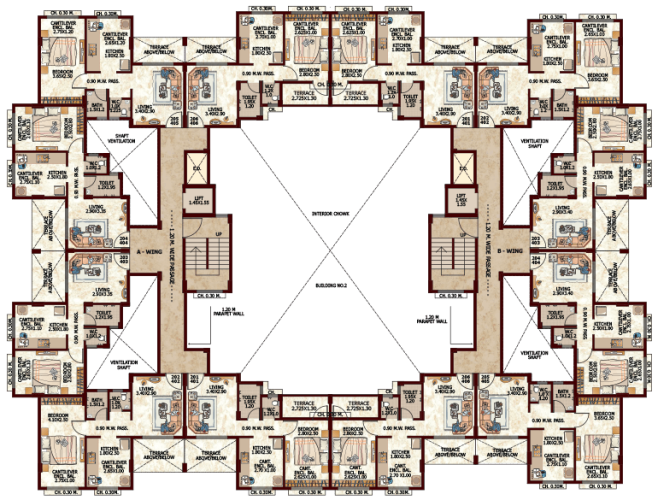

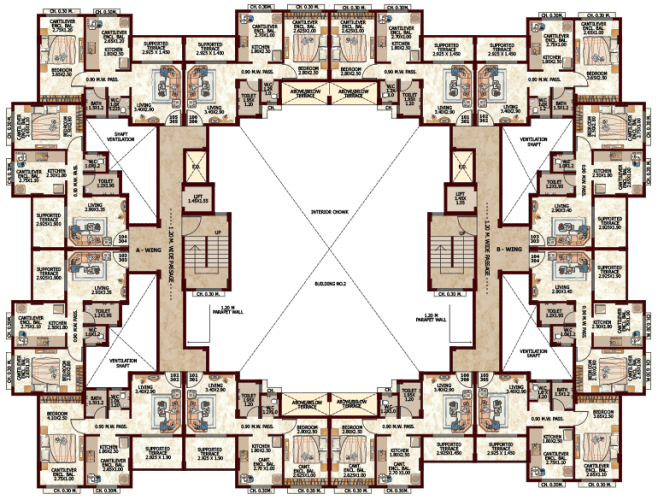

4 Floors with Stilt Parking

6 Flats per foor x 2 Wings

All 1BHK Flats

Quality Construction with Earthquake Resistant RCC Structure

Branded (Lift) Elevators

Loans Available & Approved by HDFC Bank

Need any help Buying?

Project Specification

FLOORING

- Vitrified fooring in all rooms

- Anti-skid fooring in all bathroom

KITCHEN

- Granite Kitchen Platform with Big S.S Sink SINCORE MAKE (21”x18” Size) - 304 Grade

- Decorative Ceramic Tiles in the Entire Kitchen upto Loft

DOORS & WINDOWS

- Wooden framing to all the doors

- Decorative Main Entry Door

- Anodized Aluminium Sliding Window

- Windows in Hall & Bedroom

ELECTRIFICATION

- Concealed Copper Wiring with Modular Switches

- Provisions for Cable TV, Wi-Fi & Telephone

- Adequate electrical points in all rooms

WALLS & PAINTS

- Internal Wall Finish with Gypsum + 2 Coats of Putty

- Rubbed and cleaned with SandPaper

- Emulsion/Plastic Paints for Internal Walls

- Acrylic Paints for External Walls

BATHROOMS

- Special Waterproofing Treatment

- Branded tiles with granite framing entry for bathroom

- Concealed Plumbing Fixtures of premium quality

- Branded Sanitary Wares & C.P Fittings

LIFT

- Lift of a Reputed Company

Terrace

- Special water proofing treatment for terrace China Chips

HUGE WATER TANK

- Undergroud & Overhead Water Tank with adequate storage capacity

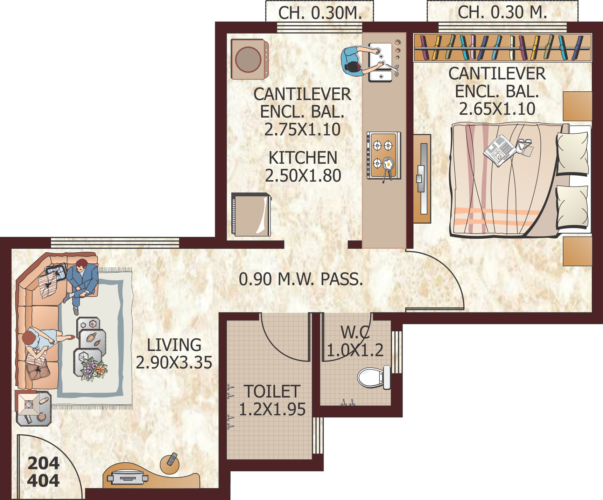

Floor Plans

Technicals & Value Additions

Sand Wash

Cover Blocks

Steel Anchoring & Lintel Beam

Groove Cutting (With Grinder/Cutter)

Providing Socket & Polymer Grouting

Anchor Fastener (In Door Frames)

Removal of Fungus (Before Plastering Walls)

Gabda (Bathroom)

Bathroom Waterproofing

Curing of RCC & Plaster

Galvanized Railing

Tiles

Sand Wash

SAND WASH

- Sand is washed through the Sand-Wash Machine at site for the entire project.

- It is used to remove the silt. Entire Sunk portion is cleaned with High Pressure Pump.

Cover Blocks

1

2

Cover Blocks

- Providing cover blocks in RCC at regular intervals, so that corossion of steel will not take place.

Steel Anchoring & Lintel Beam

4

3

2

1

Steel Anchoring & Lintel Beam

- Anchoring of steel in column for providing reinforced

concrete band in masonry work at 1.0m height.

Groove Cutting (With Grinder/Cutter)

3

2

1

4

5

Groove Cutting (With Grinder/Cutter)

- Groove cutting in the masonry wall is done around the

RCC frame structure, which is then filled with cement +

polymer later stone pieces are inserted in it. - Result : Separation of RCC Structure & Wall will not take

place in future.

Providing Socket & Polymer Grouting

14

3

1

2

Providing Socket & Polymer Grouting

- Result : Separation of RCC Structure & Wall will not take

place in future. - Grouting : Cement & polymer is mixed with water,

pressure grouting is done in the above sockets. - This process is done all around the external periphery of

the building & at every drainage outlet point from the

bathroom.

Anchor Fastener (In Door Frames)

Anchor Fastener (In Door Frames)

- Frames Installed with Nylon Anchor Fastener.

- Door Fixed with Anchor Fastener

Removal of Fungus (Before Plastering Walls)

2

1

Removal of Fungus (Before Plastering Walls)

- Fungus developed on masonry work during the curing

period is cleaned with a high pressure (160 bar) pump

before the plastering stage.

Gabda (Bathroom)

Gabda (Bathroom)

- Bathroom outlets (Gabda) are done with a core-cutting

machine.

Bathroom Waterproofing

31

4

3

5

Bathroom Waterproofing

- Entire Sunk portion is cleaned with High Pressure Pump

- Stone Pieces are inserted in the junction of WALL &

FLOOR with Cement Paste. - Later polymer and cement mixture is used which is then applied entirely on the SUNK PORTION.

Curing of RCC & Plaster

2

1

Curing of RCC & Plaster

- RCC Columns are wrapped with Jute cloth and curing is

done for 21 days. - The plaster area is wrapped with Jute Cloth (wherever

possible) and curing is done for 15 days.

Galvanized Railing

8

1

Galvanized Railing

- All the railing of terraces, outside the hall and outside

the bedroom are manufactured from Hot Dipped

Galvanized Section.

Tiles

12

10

11

Tiles

- Providing full kitchen & bathroom with 2 ft. x 1 ft. tiles (all sides).

- Upto the loft level.

- Bathroom Flooring with Anti-Skid tiles.

- Vitrified Floor Tiles with 32 inch x 32 inch size.

List of Chemicals Used for the Construction

-

SIKA LATEX SBR (POLYMER)

Polymer is used as a binding coat between rcc structure & wall. It is also used for grouting purpose and making cement paste. -

SUPERCON 100

Melamine based superplasticizer. It is used to achieve high quality concrete and plaster. -

KP / HP-350

Epoxy used for anchoring steel reinforcement in concrete (for providing reinforced concrete band in walls). Also used for the fixing of doors & window frames (marble/granite), to provide strong bonding with the wall. -

KP - CPCC

Cement polymer cement system. holdfasts which are used for the erection of wooden frame, are dipped in kp-cpcc so as to avoid corrosion. -

SILICONE SEALANT

It is neutral cure weather proofing silicone sealant. Used for sealing any gaps in window frame to avoid penetration of water through gaps in marble.

Gallery

Current Project Status

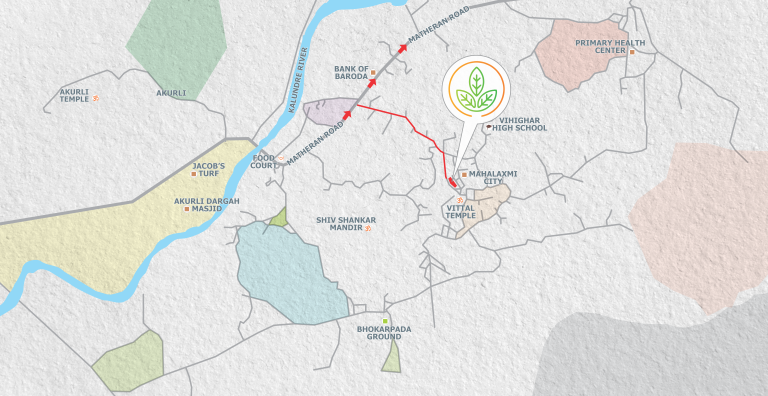

A Timeless Location that has it all

One of the highlights of the location of this residential project is that it’s easily accessible from the Airport expressway, as well as the Outer Ring Road, So whether you’re heading towards the Central Business District, or on your way to the Airport, the commute is quick and simple.

Connect to our Sales Person

Call

8567 891 891 / 8567 892 892

sales@parshwacity.com